Different foods should choose food bags with different material structures according to food characteristics, so what kind of food is suitable for what kind of material structure as food bags? Professional flexible packaging manufacturer Shunfa packing to interpret for you, the need for customized food packaging bag customers can refer to it.

1. Cooking bag

Product requirements:

It is used for the packaging of meat, poultry, etc., requiring good packaging barrier, bone hole breaking resistance, sterilization under cooking conditions, no cracking, no shrinkage, no odor.

Design structure:

Transparent class: BOPA/CPP, PET/CPP, PET/BOPA/CPP, BOPA/PVDC/CPP, PET/PVDC/CPP, GL-PET/BOPA/CPP

Aluminum foil: PET/AL/CPP, PA/AL/CPP, PET/PA/AL/CPP, PET/AL/PA/CPP

Reason:

PET: high temperature resistance, good rigidity, good printability, high strength.

PA: High temperature resistance, high strength, flexibility, good barrier, puncture resistance.

AL: Best barrier, high temperature resistance.

CPP: High temperature cooking grade, good heat sealing, non-toxic and tasteless.

PVDC: high temperature barrier material.

GL-PET: ceramic steam coating, good barrier, microwave penetration.

For specific products to choose the right structure, transparent bags are mostly used for cooking, and AL foil bags can be used for ultra-high temperature cooking.

2. Extruded snack food packaging bag

Product requirements: oxygen resistance, water resistance, light resistance, oil resistance, fragrance protection, appearance, bright color, low cost.

Design structure:

BOPP/VMCPP

Reason:

Both BOPP and VMCPP are scratchy,BOPP has good printability and high gloss. VMCPP has good barrier property and keeps fragrance and dampness. CPP also has good oil resistance.

3. Cookie bag

Product requirements:

Good barrier, strong light shading, oil resistance, high strength, odorless and tasteless, packaging very scrape.

Design structure:

BOPP/EXPE/VMPET/EXPE/S-CPP

Reason:

BOPP has good rigidity, good printability and low cost. VMPET has good barrier, light, oxygen and water resistance. S-CPP has good low temperature heat sealing and oil resistance.

4. Milk powder packaging bag

Product requirements:

Long shelf life, flavor protection, anti-oxidation deterioration, anti-moisture caking.

Design structure:

BOPP/VMPET/S-PE

Reason:

BOPP has good printability, good luster, good strength and moderate price.

VMPET has good barrier property, light avoidance, good toughness, metallic luster and enhanced PET aluminum plating is preferred, with thick AL layer. S-PE has good anti-pollution sealing property and low temperature hot sealing property.

5. Tea bags

Product requirements:

Anti-deterioration, anti-discoloration, anti-taste, that is, to prevent the oxidation of protein, chlorophyll, catechuic acid and vitamin C contained in tea.

Design structure:

BOPP/AL/PE, BOPP/VMPET/PE, KPET/PE

Reason:

AL foil, VMPET, KPET are excellent barrier materials, good barrier to oxygen, water vapor, odor. AK foil, VMPET light resistance is also very good. The product is moderately priced.

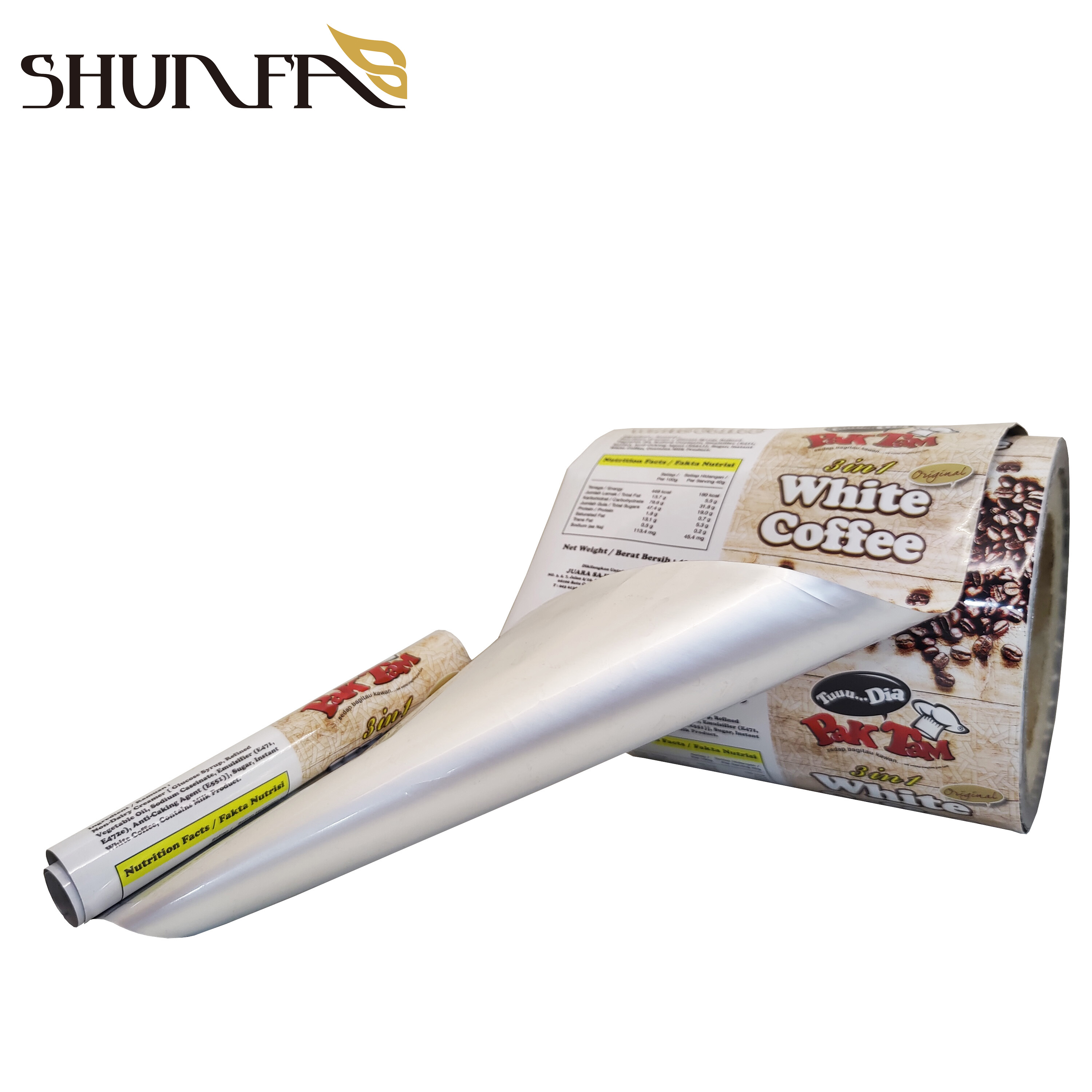

6. Grind coffee bags

Product requirements:

Anti-water absorption, anti-oxidation, resistant to the hard lump of the product after vacuuming, to keep the volatile coffee, easy to oxidize the flavor.

Design structure:

PET/PE/AL/PE, PA/VMPET/PE

Reason:

AL, PA, VMPET has good barrier, water and air resistance, and PE has good heat sealing.

7. Chocolate packaging bags

Product requirements:

Good barrier, avoid light, beautiful printing, low temperature heat seal.

Design structure:

Pure chocolate polish/ink/White BOPP/PVDC/ Cold seal adhesive

Nut chocolate gloss oil/ink /VMPET/AD/BOPP/PVDC/ cold seal adhesive

Reason:

PVDC, VMPET are high barrier materials, cold sealing glue can be sealed at very low temperature, heat will not affect the chocolate, because the kernel contains more oil, easy oxidation deterioration, so the structure of the increase of oxygen blocking layer.

Post time: Jul-19-2023